Wheel brushes without shaft

The definition of a wheel brush is one that has a continuous cylindrical body with an axial drilled hole without a shaft and is filled on the outer circumference of the body.

Text

Information

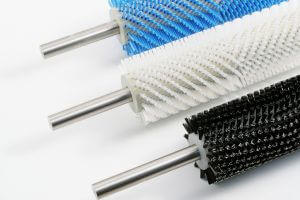

Roller brushes

The term 'roller brush' refers to brushes that have a continuous cylindrical body, with trunnions on both sides or without an axial drilled hole. The fill is on the outer circumference of the body. It is optimally tailored to the specific application purpose in terms of its diameter, surface density and bundle diameter.

Text

According to intended use, the shaft is made from steel or stainless steel. The shaft ends are configured to the requirements of the customer.

Information

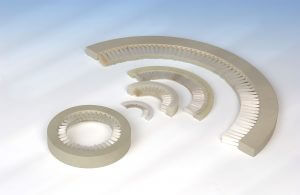

Half-shell wheel brushes

The most common use of half-shell wheel brushes is for applications where it is difficult to change a wheel brush, when, for example, the shaft is permanently fixed.

Text

Information

Special wheel or roller brushes

Any wheel brush typee that is different from the wheel brushes on page 12 is considered to be a special. We manufacture these according to the special wishes and requirements of our customers.

Our modern and versatile engineering department is suitably equipped to meet almost every customer request with regard to shape and configuration. These special versions provide you with an almost unlimited range of options, e.g. profiled body or filament surfaces, conical or recessed drilled axle holes, specially designed bearing or fixing bushes etc.

For special applications it is possible to manufacture wheel or ring brushes with the fill on the inside. Depending on the diameter or the application, the wheel or ring brush is produced as a half-shell or a closed ring. As with our other brushes, special configurations are possible.